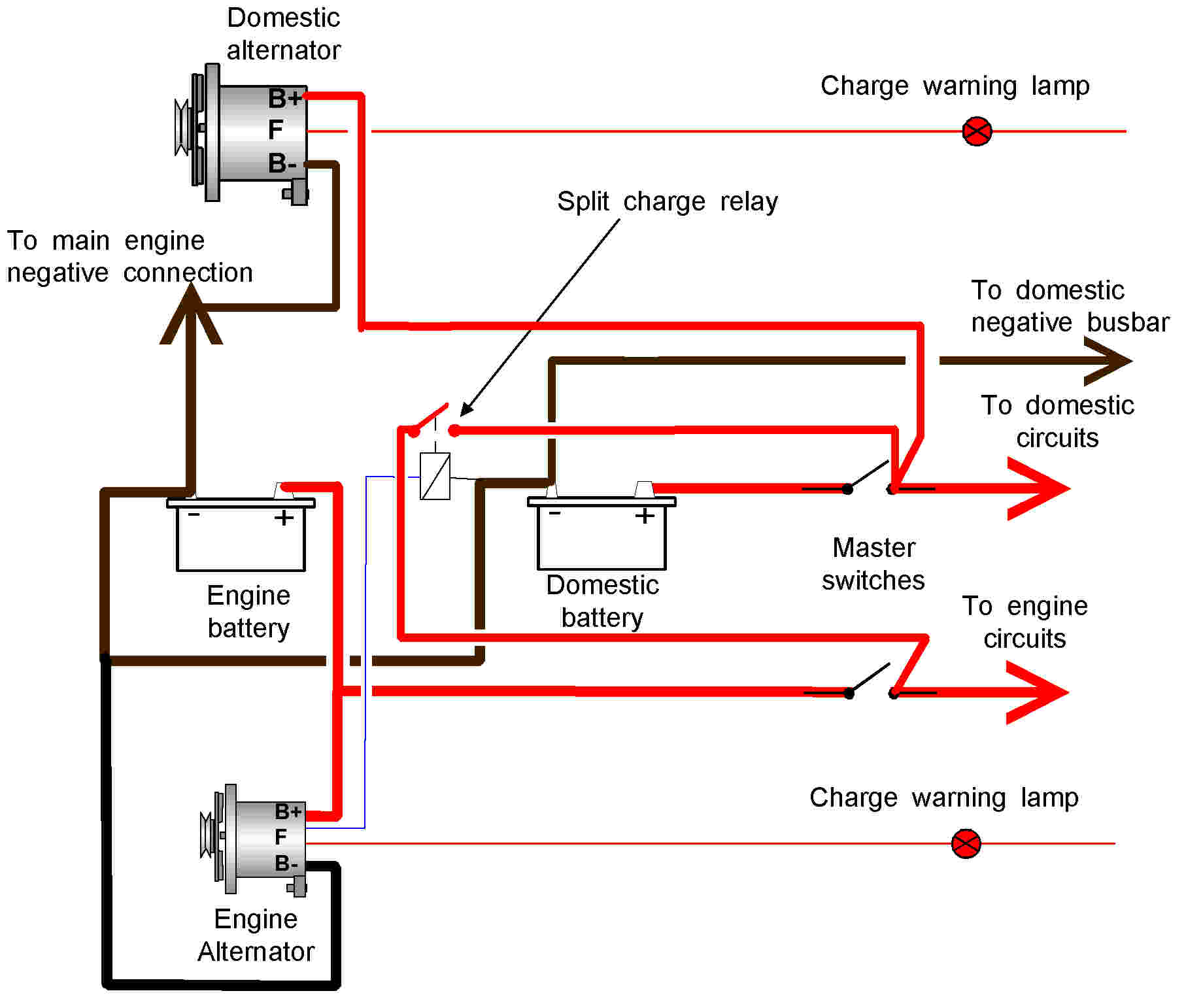

Car Alternator Wiring Diagrams are crucial for understanding the electrical system of a vehicle. They provide a visual representation of how the alternator is connected to the battery and other electrical components. By studying these diagrams, mechanics and DIY enthusiasts can troubleshoot electrical issues, perform maintenance, and make necessary repairs.

Why Car Alternator Wiring Diagrams are Essential

Car Alternator Wiring Diagrams are essential for the following reasons:

- Provide a detailed overview of the alternator’s electrical connections

- Help in diagnosing electrical problems

- Assist in proper installation and repair of the alternator

How to Read and Interpret Car Alternator Wiring Diagrams

Reading and interpreting Car Alternator Wiring Diagrams may seem overwhelming at first, but with a little practice, it can become second nature. Here’s how you can effectively interpret these diagrams:

- Start by identifying the key components in the diagram, such as the alternator, battery, and various connections.

- Follow the wiring lines to understand how the electrical current flows through the system.

- Pay attention to color codes and symbols used in the diagram to differentiate between different wires and components.

Using Car Alternator Wiring Diagrams for Troubleshooting Electrical Problems

Car Alternator Wiring Diagrams are invaluable tools for troubleshooting electrical problems in a vehicle. Here’s how they can be used effectively:

- Identify any loose or damaged connections by comparing the actual wiring with the diagram.

- Check for voltage drops or irregularities in the electrical system by following the wiring diagram.

- Trace the flow of current to pinpoint the source of an electrical issue and make necessary repairs.

Importance of Safety When Working with Car Alternator Wiring Diagrams

When working with electrical systems and using Car Alternator Wiring Diagrams, safety should always be a top priority. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on any electrical components to prevent electrical shocks.

- Use insulated tools and wear protective gear, such as gloves and safety glasses, to avoid injuries.

- Double-check all connections and wiring before reassembling the system to ensure everything is properly secured.

Car Alternator Wiring Diagram

Simple 12v Alternator Wiring Diagram

[2 Wire, 3 Wire, and 4 Wire] Alternator Wiring Diagram – Drill and Driver

![Car Alternator Wiring Diagram [2 Wire, 3 Wire, and 4 Wire] Alternator Wiring Diagram - Drill and Driver](https://i1.wp.com/www.drillanddriver.com/wp-content/uploads/2022/12/4-wire-alternator-wiring-diagram-2.jpg)

Car Alternator Wiring Connections

Basic Car Alternator Wiring Diagram

Alternator Car Wiring Diagram

Wiring A Alternator Diagram – flilpfloppinthrough